Types Of Roof Flashing - Roof Repair Services

- Home

- Types Of Roof Flashing

Car Repairing

- July 11, 2024

- By: roofrepair_admin

- General

- Comments: 0

Types Of Roof Flashing

Roof flashing is an essential component of any roofing system, playing a crucial role in preventing water damage and ensuring the longevity of your home. It acts as a seal between the different parts of the roof and other building components, directing water away from vulnerable areas and towards the gutters. Without proper flashing, your roof is susceptible to leaks, which can lead to significant damage over time. Understanding the types of roof flashing and their specific applications can help homeowners and contractors alike ensure that a roof is watertight and durable.

Understanding Roof Flashing

Roof flashing is a thin material, typically made from metal, that is installed at critical areas of the roof to prevent water infiltration. These areas include joints, valleys, chimneys, and around any roof penetrations, such as vents and skylights. The primary purpose of flashing is to direct water away from these critical areas and prevent it from causing damage to the roof structure or the interior of the home. By providing a watertight seal at potential entry points for water, flashing plays a pivotal role in the overall waterproofing and protection of the roofing system.

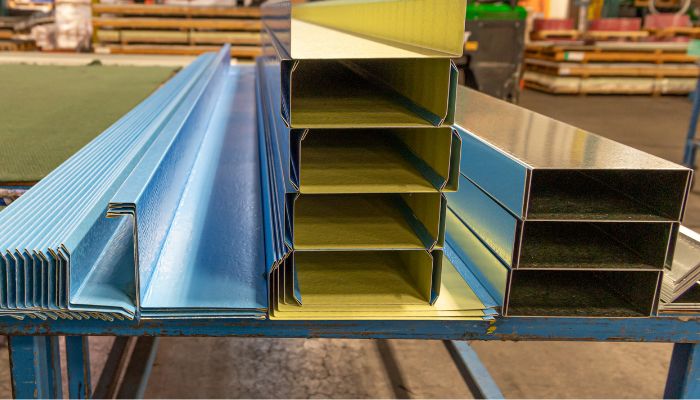

Common Materials Used in Roof Flashing

The effectiveness of roof flashing largely depends on the quality of the materials used. Here are some of the most common materials for roof flashing, each offering its own set of benefits:

Galvanized Steel

Galvanized steel is one of the most popular materials for roof flashing due to its durability and resistance to corrosion. It’s a cost-effective option that provides a long lifespan when properly installed and maintained. Galvanized steel is particularly suited for areas with harsh weather conditions, as it can withstand significant wear and tear.

Aluminum

Aluminum flashing is lightweight, rust-resistant, and easy to shape, making it an ideal choice for complex roof designs. It’s also compatible with various roofing materials, including asphalt shingles and metal roofing. Aluminum offers an aesthetically pleasing finish and can be painted to match the roof or other building components, enhancing the overall aesthetic appeal of the home.

Copper

Copper is a premium flashing material known for its exceptional durability, long lifespan, and natural ability to form a protective patina over time. This patina not only adds to the aesthetic appeal of the roof but also enhances the material’s resistance to corrosion. Copper flashing is often used in high-end roofing projects for its beauty and reliability.

Lead

Lead flashing is highly malleable, making it perfect for sealing complex joints and irregular shapes on the roof. It’s extremely durable and offers excellent waterproofing capabilities. However, due to health and environmental concerns associated with lead, its use has become less common in residential applications.

PVC and Other Plastics

For those looking for a non-metallic option, PVC and other plastic materials offer flexibility and resistance to corrosion. These materials are typically used in conjunction with other roofing components, such as vent pipe flashing, and are favored for their ease of installation and low cost. However, they may not provide the same level of durability and longevity as metal flashing options.

Types of Roof Flashing

Understanding the different types of roof flashing is key to ensuring that each part of the roof is adequately protected. Here are some of the most common types:

Continuous or Apron Flashing

This type of flashing is used along the joint where a vertical surface meets a sloped roof plane, such as against a dormer or the front of a chimney. Continuous flashing, also known as apron flashing, provides a straight, uninterrupted path for water to be directed away from the roof.

Step Flashing

Step flashing is installed where a roof meets a vertical wall, such as at the sides of chimneys or dormers. It consists of a series of rectangular pieces that are layered with shingles to ensure water flows away from the wall and back onto the roof or into the gutters.

Valley Flashing

Valleys, where two roof planes meet, are particularly vulnerable to water leaks. Valley flashing is installed beneath the shingles in these areas to provide an extra layer of protection. Open valleys, which are left exposed, can be particularly aesthetically pleasing if done with quality materials like Colorbond steel or copper, offering both functionality and visual appeal.

Drip Edges

Drip edges are installed along the edges of the roof to direct water away from the fascia and into the gutters. This type of flashing is crucial in preventing water from getting underneath the roofing materials at the edges of the roof.

Vent Pipe Flashing

Vent pipes require special flashing to prevent leaks. This typically involves a rubber seal that fits around the pipe, combined with a metal or plastic base that integrates with the shingles or other roofing materials to create a watertight seal.

Chimney Flashing

Chimney flashing involves multiple components, including step flashing, counter flashing, and sometimes a cricket or saddle to prevent water from pooling behind the chimney. Properly installed chimney flashing is critical to preventing leaks in these highly vulnerable areas.

Each type of flashing has its specific application and installation requirements. Using quality materials and ensuring that each piece of flashing is installed correctly are key factors in achieving a watertight roof that stands the test of time. Whether you’re installing a new roof or addressing roof leaks, understanding the different roof flashing types and their roles within the roofing system can help you make informed decisions about your roofing needs and ensure the longevity of your home’s roof.

Installation Considerations

Proper installation of roof flashing is paramount to ensure the effectiveness of the roofing system in preventing water damage. Each type of flashing requires specific techniques to ensure it performs its function of directing water away from vulnerable areas of the roof. For instance, installing valley flashing involves laying the material into the valley and securing it in place before the roof coverings are applied, ensuring a seamless path for water flow. Similarly, step flashing needs to be integrated with each course of shingles or other roofing materials to maintain a watertight seal against vertical surfaces.

The complexity of installing flashing around chimneys, skylights, and other roof penetrations underscores the importance of professional expertise. These areas often require a combination of continuous, step, and sometimes counter flashing to fully protect against water infiltration. The use of quality materials, such as Colorbond steel for metal roof flashings or durable PVC for vent pipe flashing, also contributes to the longevity and performance of the flashing system.

Maintenance and Repair

Regular maintenance is crucial to extend the lifespan of roof flashings and prevent leaks. Inspections should focus on checking for signs of wear, corrosion, or damage to the flashing, especially after severe weather events. Areas around chimneys, valleys, and other critical points should be given special attention to ensure the flashing remains intact and functional.

Over time, even well-installed flashing can become a source of leaks if not properly maintained. For example, sealant used around vent pipe flashing may degrade, or metal flashing may corrode, creating gaps where water can enter. In such cases, prompt repair or replacement of the affected flashing is necessary to prevent water damage to the roof structure and interior of the home.

Homeowners are often advised to seek a free estimate from roofing professionals to assess the condition of their roof’s flashing and receive recommendations for maintenance or replacement. This proactive approach can save significant costs and inconvenience by addressing issues before they lead to major leaks or water damage.

The Role of Flashing in the Roofing System

The integration of flashing into the roofing system is a critical aspect of any roofing project. From the initial design phase, the types of roof flashing to be used must be considered alongside the selection of roofing materials and the overall structure of the roof. This ensures that all components work together to provide waterproofing and protect the home from water damage.

For example, the installation of drip edges at the eaves and rakes of the roof helps to direct water into the gutters, while apron flashing at the base of a chimney ensures that water flows around this potential entry point. Similarly, the use of corner flashings and barge capping can further enhance the roof’s ability to shed water effectively, especially in areas prone to heavy rainfall or snow.

Choosing the Right Flashing for Your Roofing Needs

With the variety of flashing options available, choosing the right type for your roofing needs can seem daunting. Factors to consider include the material and design of the roof, the climate, and specific architectural features of the home that may require specialized flashing solutions.

Metal roofing, for instance, may benefit from custom metal roof flashings designed to accommodate the expansion and contraction of the metal panels. Similarly, homes in areas with high wind or heavy snowfall may require more robust flashing systems to prevent leaks under extreme conditions.

Consulting with roofing professionals can provide valuable insights into the most appropriate flashing options for your home. They can recommend quality products and installation techniques that are suited to your roofing materials, design preferences, and budget, ensuring that your roof is well-protected against water infiltration for years to come.

Conclusion

Roof flashing is an indispensable component of any roofing system, playing a crucial role in preventing water leaks and protecting the home from water damage. Understanding the different types of roof flashing and their applications is essential for homeowners and roofing professionals alike. Whether it’s metal roof flashing, valley flashing, or chimney flashing, each type serves a specific purpose in directing water away from the roof’s vulnerable areas.

The choice of material, from galvanized steel to Colorbond steel, and the quality of installation are critical factors in the effectiveness and longevity of the flashing. Regular maintenance and timely repairs are also crucial to ensure that the flashing continues to perform its protective role throughout the lifespan of the roof.

Ultimately, the success of any roofing project depends on the careful selection and proper installation of roof flashings. By prioritizing quality materials and professional workmanship, homeowners can ensure that their roofing system is durable, aesthetically pleasing, and capable of withstanding the elements, thereby safeguarding their home against the risks of water damage.